|

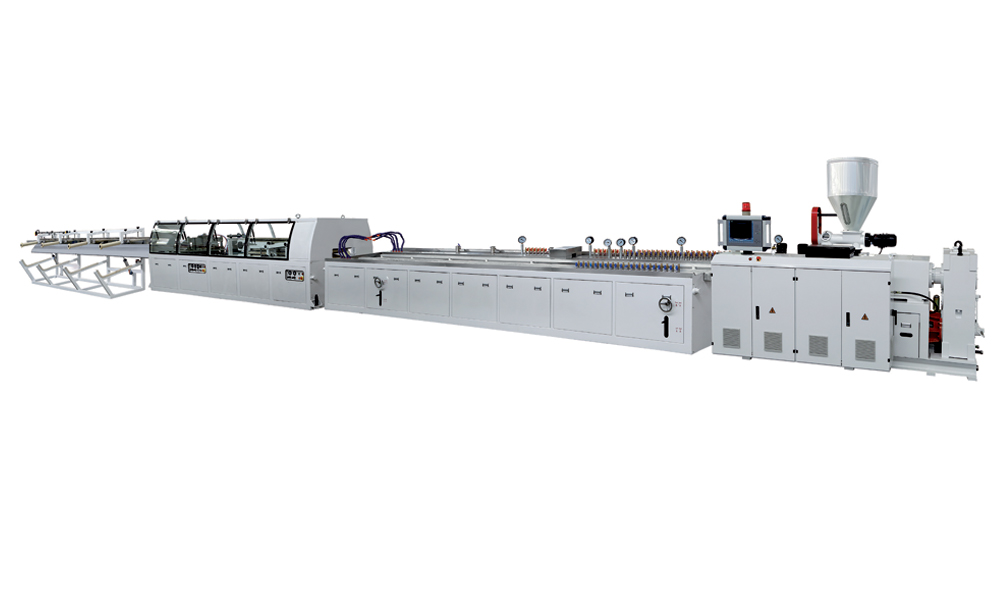

PVC墙板天花板生产线

收藏

生产线特点和功能 YF系列PVC异型材生产线主要用于PVC门窗型材、宽幅门板、窗台板挤出。该生产线可以根据不同型材断面及模具,选用不同规格的平行(锥形)双螺杆挤出机,并配置相应的真空定型台,牵引机,切割机,翻料平台等辅助设备。 主要挤出量可以在每小时60公斤到700公斤之间任选。牵引机采用我公司独特升降技术,工作平稳,可靠性好,牵引力大。真空定采用特殊加大洞流冷却系统型,以满足高速挤出的需要。切割机移动速度与牵引速度保同步,全部采用进口PLC电控制,设计合理,运行稳定切割,并配备粉尘回收装置。根据不同的磨具,定型台可选用4米、6米、8米、11米等规格。配置平行双螺杄挤出机,特别适用于型材高速挤出。 Characteristics and functions of the production line YF series PVc profile extrusion line is mainly use in Pvc door& window profile, wide door board, window board, extrusion of multi-holes tube for passing through lines. For different sectional surface and die head, twin parallel (conical) screw extruder of different specifications can be chosen together with corresponding vacuum calibrating table, haul-off unit, tilter. etc. Capacity of main frame can be optionally chosen from 60-700Kg/h The haul-off unit has applied unique lift technique of our JINHU CO. Stable work. good reliability and large pulling force. Vacuum setting has applied special enlarged vortex cooling system which is good for cooling and calibrating so as to meet demand of high speed extrusion. Movement speed and drawing speed of cutting machine keep synchronous. All movements are controlled by imported PLC, the design is reasonable, the operation is stable, also it can conduct automatic cutting with fixed length. Powder& dust suction device can be provided With different die tooling, the tilter platform can choose such specifications as 4-meter, 6-meter, 8-meter, 11-meter etc. With twin parallel screw extruder, it is particularly suitable for high speed extruding of profile material. 主要技术参数 Main technical parameter

|